What technical debt from 1st generation horizontal wells?

Are your horizontal wells old age or new age?

Great surprises come when using vintage first generation horizontal wells in a flood. Existing legacy wells were not set up to take advantage of the prevailing permeability direction.

Great surprises come when using vintage first generation horizontal wells in a flood. Existing legacy wells were not set up to take advantage of the prevailing permeability direction.

This blog post is brought to you by Proven Reserves Exploitation, one of our information partners. Photo credit Seattle Municipal Archives Nein commercial use of der AppIntel content.

One operator converted an injector from horizontal wells he inherited from previous operators. The wells had been drilled using the thinking of last decade. The producers in the pool watered out almost immediately. He lost his job.

See his plans and hopes by downloading his application documents from our self serve web portal.

Get details of this cool tech Subscribers get them for freeWhat is technical debt?

Technical debt is the amount of money that must be spent to correct an oil field from the way things were done before. Tech debt is incurred by using shortcuts in the past. It is also incurred by ignoring maintenance. It also comes from new and changing technology.

1st generation horizontal wells

Horizontal wells have come a very long way since they were first introduced in the Austin Chalk of Texas in the early 1990s.

1st generation horizontal wells were drilled North-South or East-West -- parallel to lease boundaries.

1st generation horizontal wells were drilled North-South or East-West -- parallel to lease boundaries.

1st generation horizontal wells were fracked at even intervals regardless of formation porosity, permeability, organic content and open fracture orientation.

Legacy operators drilled parallel to lease boundaries because they believed more wells could drilled per lease. But industry has found since that such legacy wells produce less than wells drilled to take advantage of directional permeability trends.

?subject=I want just a few email alerts&body=Sign me up for a few email area alerts when a new horizontal injector is submitted. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:___%0D%0A%0D%0APricing: www.appintel.info/just-alerts/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us to buy just a few cheap and cheery email alerts.

Since drilling the first ones, industry has learned that horizontal wells never encounter homogeneous formation along the entire length of the well. Ignoring heterogeneity severely impacts the performance of a horizontal well.

Horizontal wells need to take advantage of formation heterogeneity.

The best production (and payout) comes from horizontal wells that consider directional permeability.

The best horizontal wells are rarely those drilled North-South. Wells drilled considering directional perm produce up to four times higher rates than those drilled parallel to lease boundaries.

Technical debt of 1st generation horizontal wells

One fellow considered the technical debt of 1gen horizontal wells in connection with secondary recovery. He said "I don't care." His business model was to drill as many wells as possible and then sell them to someone else. Any future problems would belong to the buyer. This is a classic example of planned technical debt.

Some don't care. Some don't know any better.

What can be done? Is recovery limited forever? Can a field ever recover from this type of technical debt?

?subject=Contact me about improving flood infill performance&body=Help me find the effect of directional permeability on flood infills.%0D%0AField__________%0D%0AFormation_______________%0D%0AMy phone_______________">contact Proven. We can help you take advantage of directional permeability and avoid poor infill performance.

The cost of ignoring advances in horizontal well technology

Still drilling North-South?

Still drilling East-West?

Still drilling parallel to lease boundaries?

Still fracking at even intervals without regard to rock quality?

The cost is higher;

The cost is higher;

Production rate is poorer;

Reserve recovery is poorer;

Well payout is poorer;

Well failure rate is higher.

Horizontal wells should be completed in the best pay. Hoping to frack into something good? Experience shows this is unlikely.

Horizontal wells that are drilled and completed with rock quality in mind have a far better payout than wells drilled without any regard to rock quality.

Are your new horizontal wells disappointing?

Many 1st generation horizontal wells experience poor performance from a host of issues. A few include:

- Directional permeability

- Stimulation sites that ignore reservoir character

- Post primary gas cap movement

- Post flood saturation changes

?subject=Help me find the horizontal well failures of other operators&body=Help me find the horizontal well failures of other operators.%0D%0ACan AppIntel help?%0D%0AMy phone_______________">Contact sales for a trial of AppIntel.

Unexpected saturations encountered by a horizontal well are difficult to shut off. Offending perfs in a horizontal well are tough to locate and even tougher to shut off. Polymer diverters have had poor success.

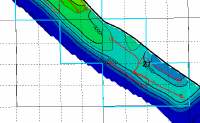

Drill horizontal -- but which direction?

If you don't drill North-South, what direction should you choose? That depends on the rock, the fluid and future enhanced recovery plans.

If you don't drill North-South, what direction should you choose? That depends on the rock, the fluid and future enhanced recovery plans.

The azimuth direction of the best primary production wells is different than in a flood.

It is important to consider directional permeability in your choice.

Horizontal field re-redevelopment

Can a field developed with 1st generation horizontal wells be redeveloped with next generation, modern horizontals?

Some fields can be redeveloped with little negative impact from 1st generation horizontal wells. But redevelopment success depends on many factors, not on rules of thumb.

The first step toward improving recovery is to embrace the paradigm shift away from 1st generation horizontal wells.

?subject=Contact me about your simulation of Hz redvelopment&body=Is it worth while to fix the field where all the horizontal wells were drilled North/South?%0D%0ATell me about your simulation process to show the pros and cons of horizontal redevelopment with next generation wells.%0D%0AField__________%0D%0AFormation_______________%0D%0AMy phone_______________">Contact Proven for our testing simulation on your field.

Next generation horizontal wells

Why drill wells invented last century? The only advances are not in stimulation technology.

Modern horizontal wells are drilled in a direction that takes into account directional permeability.

They are drilled considering future enhanced recovery.

They are stimulated along the wellbore in the best rock quality.

Next-generation horizontal wells cost less and produce more.

Why drill anything but next-generation horizontal wells?

Tags: Fracturing, Tight, Flood

Granger Low 26 Aug 2024

Granger Low 26 Aug 2024

Don't blow the lid

Fracking into a neighboring well causes a blowout

Continuing Canadian thermal innovation doubled oil production

Experimental Propane Solvent co-injection in thermal

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Three corner shots

Can you find them?

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Celebrating 2025, a year of innovation

Oil and gas paradigm shifts this year

RTF: Most refused submission type in November

Leading indicators from industry

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share