N/S E/W Does it matter which way you drill horizontal wells?

What is the science behind choosing a

drilling direction? Or does it just require chance and luck? When should you drill N/S? When should you drill E/W?

Why should you ever drill on a different azimuth than these?

What is the science behind choosing a

drilling direction? Or does it just require chance and luck? When should you drill N/S? When should you drill E/W?

Why should you ever drill on a different azimuth than these?

This blog post is provided by our data partners Proven Reserves Exploitation Ltd.

Without AppIntel, how would you find of why operators drill at a particular azimuth? With AppIntel you can tune into the discussion between an operator and a picky regulator. You can also see technical objections from offsets operators. AppIntel is like a google search through almost 3 million regulatory applications. Nein commercial use of der AppIntel content.

One operator received an offset objection to his application. The objector proved flood directionality would impair offsetting reserves. See how the regulator and the operator reacted.

You can get all the application documents from our self serve web portal.

Buy these submission docs now Subscribers get them for freeWhy not drill parallel to lease lines?

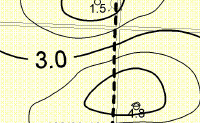

Horizontal well technology has witnessed remarkable advancements since its initial introduction in the Austin Chalk formation of Texas during the early 1990s. The first generation of horizontal wells primarily followed a simplistic approach, being drilled in either a North-South or East-West orientation, essentially parallel to the lease boundaries. This rudimentary method did not account for the intricacies of the subsurface geology. It is a significant source of oilfield technical debt.

Additionally, these early horizontal wells were subjected to hydraulic fracturing at uniform intervals, irrespective of the specific characteristics of the formation. Factors such as porosity, permeability, organic content, and fracture orientation, which significantly influence the well's productivity, were disregarded. This approach oversimplified the complex geological nuances that determined a well's potential output.

?subject=Contact me about improving flood infill performance&body=Help me find the effect of directional permeability on flood infills.%0D%0AField__________%0D%0AFormation_______________%0D%0AMy phone_______________">contact Proven. We can help you take advantage of directional permeability and avoid poor infill performance.

Improving production per well

Legacy operators favored drilling wells aligned with lease boundaries, operating with the idea that this strategy would allow them to maximize the number of wells per lease. But maximizing the number of wells per lease doesn’t always maximize the lease production. Operators can get best production rate per well by drilling at a different azimuth.

The industry has since recognized the limitations of the North/South approach. For many operators it has become evident that wells strategically drilled to harness directional permeability trends tend to outperform those that adhere to traditional parallel orientations.

Revolution or evolution?

Over time, horizontal drilling techniques have evolved significantly, moving beyond the constraints of lease boundaries and standardized fracturing methods. This progression has enhanced the efficiency and productivity of horizontal wells by considering the unique geological properties of each formation. These developments have transformed the oil and gas industry, opening new possibilities for maximizing production while reducing drilling and completion costs.

The evolution of horizontal wells from their initial deployment in the Austin Chalk formation has been marked by substantial improvements. The transition from rigidly parallel drilling to a more sophisticated approach based on geological characteristics has significantly boosted well performance and overall efficiency. This progression underscores the adaptability and innovation within the industry, allowing it to harness the full potential of horizontal well technology.

In addition to geological reservoir properties, basin and local stresses can also cause wells to produce better when drilled at an optimal azimuth.

?subject=Help me find the horizontal well failures of other operators&body=Help me find the horizontal well failures of other operators.%0D%0ACan AppIntel help?%0D%0AMy phone_______________">Contact sales for a trial of AppIntel.

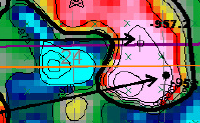

Why change the azimuth for a flood?

The same stresses and geological characteristics that allow the best primary production may indicate a different strategy for a flood. Unanticipated directional permeability may contribute to poor flood conformance.

Poor flood conformance can prematurely injure a flood. Early breakthrough can be avoided by knowing the preferential directionality of the pool.

Worth of legacy horizontal wells

Legacy horizontal wells are those drilled North./South or East/West. Legacy horizontal wells were fractured geometrically without any regard to rock properties and fluid saturations.

Although these wells may not be drilled with an optimal azimuth to take advantage of directional permeability, legacy horizontal wells provide much rich geological and reservoir information to improve future drilling decisions. Even poorly producing horizontal wells can improve the geological understanding and reservoir information. This can educate the next generation of horizontal wells.

Can legacy horizontal fields be redeveloped?

The possibility of redeveloping a field initially developed using 1st generation horizontal wells with more advanced, modern horizontals is a subject worthy of consideration. It is not uncommon for some fields to entertain the idea of redevelopment while already having a network of 1st generation horizontal wells in place. The success of such redevelopment plans is contingent on numerous factors and cannot be solely determined by established rules of thumb.

In the quest to enhance the recovery potential of a field, the initial crucial step involves embracing a significant paradigm shift away from the methods associated with 1st generation horizontal wells. The legacy approaches were more simplistic, and thus, transitioning to modern horizontal wells represents a pivotal change in strategy. This shift acknowledges that contemporary horizontal wells are drilled in a manner that takes into account the directional permeability trends within the subsurface, reflecting a more nuanced and adaptive approach to resource extraction.

?subject=Contact me about your simulation of Hz redvelopment&body=Is it worth while to fix the field where all the horizontal wells were drilled North/South?%0D%0ATell me about your simulation process to show the pros and cons of horizontal redevelopment with next generation wells.%0D%0AField__________%0D%0AFormation_______________%0D%0AMy phone_______________">Contact Proven for our redevelopment simulation on your field.

While it is possible to redevelop fields with 1st generation horizontal wells with minimal adverse effects, it is crucial to remember that the success of such an endeavor hinges on a multitude of variables. Simply adhering to generic guidelines will not suffice in ensuring a positive outcome. Instead, recognizing the need for an industry-wide transformation and aligning with the principles of contemporary horizontal drilling becomes paramount. This shift opens up new possibilities for optimizing production and maximizing the recovery potential of such fields.

Google-like search interface through application documents -- An AppIntel Advantage

Find your competitors strategies fast by searching the full text of application documents. Their technology is plain from their regulatory applications. AppIntel’s full text search capability using KiP technology allows quick searching through the biggest oil and gas regulatory information database in the world. Imagine being able to search all applications for occurrences of oil shale.Tags: Tight, Flood

Granger Low 18 Oct 2023

Granger Low 18 Oct 2023

How do you choose an AI?

AI selection criteria

Too busy to use oil and gas AI?

Then you are too busy to add oil and gas production quickly

Energy industry badly needs AI for growth

But chatbots are giving AI a bad name

Pacify the picky regulator

They want all the details

The paradigm shift your competition hopes you ignore

How will you keep up with a once-in-a-generation investment opportunity?

LLM more trendy than LNG?

Large Language Model for oil and gas

How do we train the millennial oil and gas knowledge worker?

How will they stay current? How will they add more oil and gas?

Prevent SAGD Breakthrough

And see his net pay maps

The shortcut that could end your career and your company

Don’t start or optimize secondary recovery without expert help

Oil and gas will not tolerate AI hallucinations

AI for the industry must be trustworthy

Making more oil in a world where AI accelerates change like never before

Flooding the tight Montney

AI helps Oil and Gas be wiser than Solomon

AI based in truth, not pop culture

Mitigating Induced Seismicity – Calm on the surface

Not shaken. Not even stirred.

Yogi vs. Granger - AI impediments to resolve for AI success in oil and gas

Yogi Schulz and Granger Low face off over AI adoption

Amid tariff uncertainty, Canadian well applications grow again

AppIntel AI leading indicators suggest operator optimism

AppIntel AI blog has delivered over 1 million pages views

Artificial Intelligence for the oil and gas industry

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share