8 common misconceptions about horizontal injectors

Horizontal or vertical. Which is the best injector?

Horizontal or vertical. Which is the best injector?

Horizontal or vertical. Which is the best injector?

How would you find horizontal injector applications without Appintel? AppIntel has a google-like search function to find applications with horizontal injector in the documents. Just type it in the KiP box.

One operator has decided that horizontal wells are the best injectors for her heavy oil pool. Check out her reasons for using horizontal injectors on page 3 of her application.

Get her application documents from our self serve portal.

Get details of this cool tech Subscribers get them for freeMany misconceptions

There are many myths about horizontal injectors. Here are just a few. Nein commercial use of der AppIntel content.

Myth 1. We are the first

If you are converting your first horizontal injector, you are not blazing new trails.

The first horizontal injectors were drilled in the early 1990's.

Today less than 30% of injectors in service are horizontal, but the percentage is slowly climbing.

Because you are not the first, you can see how they worked for other operators using AppIntel

Myth 2. More injectivity

Although it is true that injectors can provide more injectivity, sweep is not always uniform. Many floods have seen quick break-through using horizontal to horizontal injector/producer patterns.

These short-circuits impair sweep, reduce recovery, raise water production and drop oil production. Who wants those outcomes?

Although some companies use polymer to try to block high perm streaks, others end up reducing injection to balance sweep patterns. Seems a shame to reduce injection after converting an expensive horizontal injector.

?subject=Call me about painless voidage calculation&body=Call me about painless voidage calculation for only $100 per month.%0D%0A %0D%0AMy Name:__________ %0D%0AMy Phone Number:__________">Contact Proven to get it started.

Myth 3. You need polymer

Special polymer diverter technology may help with injection conformance.

But use of polymer doesn't fix every short circuit problem. Often plugging the best perm in an injector severely reduces injectivity of the entire well.

Nevertheless, you might try to take your flood to the next level by using polymer or some other exotic injectant.

?subject=I want a cheap and cheery one day trial of AppIntel&body=Sign me up for a one day AppIntel trial so I can check out polymer schemes. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0APricing: www.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to try it out. Search for all the polymer schemes.

Myth 4. More contact with the reservoir

Although it is true that horizontal injectors have more length in meters or feet in the reservoir rock, that brings more unpleasant surprises than you would expect. Two of those surprises are heterogeneity of the rock and of the fluid types along the wellbore.

First, the reservoir rock is not the same along the well. The more length in the reservoir an injector has, the more rock differences will appear.

Although full open hole log sets are not always run on horizontal wells, even ROP and gamma ray logs show significant variation along a horizontal well bore.

Second, fluid types and concentrations may vary along the reservoir. For example, if a gas cap is encountered at any point in a horizontal leg, you may end up injecting all your water into the gas cap. Big Fail.

?subject=Help me get more from my old flood&body=Help me tune up my old flood, improve recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for help. We add over $20 million of reserve value ninety-five percent of the time when we tune up a flood.

Myth 5. Every inch of the injector contributes

Not every inch of an injector length has great injectivity. Tight spots and shale breaks inhibit injectivity.

On the other hand, some areas of the reservoir are simply more permeable than others. Water often short circuits through these areas.

Myth 6. Formation damage is only in the toe

Some experts believe that formation damage is always worse in the toe because there is more mud pressure there. Others believe that the heel is exposed longer to drilling mud, so it is more damaged.

Rather we have found that the differences in permeability along the wellbore length contribute significantly to filter cake build up and fluid loss. Formation damage is most likely in those permeable sections of the horizontal injector.

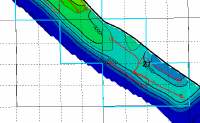

Myth 7. East/West is the right horizontal injector direction

Many operators drill their injectors in an East/West orientation parallel to the section boundaries.

on the other hand, some swear that North/South is the right horizontal injector direction.

But we believe it is better to position an injector to take advantage of high permeability direction. A properly chosen injector direction will reduce water break through.

If you want to discover the best injector direction, inject first with a vertical well and track the water breakthrough pattern. After you have learned about directional permeability from the vertical injector, your horizontal injector will be placed in a much smarter direction.

?subject=Help me learn more about directional permeability &body=Please help me take advantage of the directional permeability in my flood. %0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________%0D%0AMy flood is in field:_________%0D%0Aand formationL__________%0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for help on taking advantage of the directional permeability of your flood.

Myth 8. Everybody's doing it

Not all new injectors are horizontal. In 2017, only 62% of injectors were being drilled horizontally. That's down from 95% only 3 years before. The trend is to drill more vertical injectors.

We have discussed eight common misconceptions about horizontal injectors. There are many more. Choosing the right injector type and azimuth directions depends on permeability distribution in the reservoir.

Call Proven to help you select injectors -- we have experience on over 200 floods.

Better way to learn than reading technical papers

There is a much better way to finding field level information than reading technical information in SPE papers. SPE authors only emphasize one aspect of a technical topic. They often try to conceal much of the other critical oil and gas information to maintain their competitive advantage.

Not so with a regulatory application. The picky regulator requires all the detail. They adjudicate the application with a careful eye to understand the technical merits of the entire operation. You can learn much more from applications than SPE papers.

?subject=Help me improve my flood using Optiflood&body=Help me improve my flood using Optiflood. I understand Optiflood is a process that incorporates learnings from improving 200 floods.%0D%0A%0D%0AMy Name ________________%0D%0AMy Phone number _____________%0D%0AField ______________%0D%0APool_______________%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for their experience at using Optiflood to improve over 200 floods.

Application documents are the best source

The technical information contained in application documents are a diary of real field implementation. That's the value of reading applications.

By reading applications, you can find out which wells are injecting polymer or solvent and which ones are only injecting water. It's difficult to find that any other way.

Why ignore the field trials of others? Learn from their mistakes.

The nice thing about looking for technical information about horizontal wells from applications is that you can see the actual UWI of the injectors. Then you can go to Accumap and see the injection response. We call it ground truthing technical advances.

AppIntel: the easiest, quickest and best source of application documents

When you need to find an application, closed or approved, you can get it quickest from AppIntel. AppIntel has better search capabilities, quicker delivery, and more information about the application than any other source.

AppIntel's search functions are quicker than any other search engine. You can search by area, application type, date or just key in natural language search as if it was google.

And AppIntel's collection of historic applications is much larger than any other collection we've seen.

AppIntel adds search by UWI for applications that don't even have a UWI.

AppIntel costs less than a quarter of one person's salary. For the same price of a team of six man data-mining department, you could supply all your petroleum and facility engineers with AppIntel.

?subject=I want a cheap and cheery one day trial of AppIntel&body=Sign me up fro a one day AppIntel trial so I can check out closure statistics. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0AType of applications:___%0D%0A%0D%0APricing: www.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now for a one day trial.

Tags: Tight, Polymer, Flood, Heavy Oil

Granger Low 1 May 2019

Granger Low 1 May 2019

Don't blow the lid

Fracking into a neighboring well causes a blowout

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Three corner shots

Can you find them?

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Celebrating 2025, a year of innovation

Oil and gas paradigm shifts this year

RTF: Most refused submission type in November

Leading indicators from industry

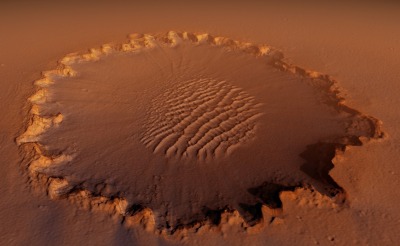

Astrobleme impacts deep well disposal scheme

Learn from the experience of other operators

Non-meridian thermal wells

Still drilling horizontal wells N‑S? Why?

Steam surfactant co-injection

Want to win? What is your competitive advantage?

Surprise! Sour gas production from a sweet thermal scheme

Dealing with surprises in the oil and gas industry. What to do next.

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share