10 ways to prevent flow to surface

And prove it to the regulator

What's the likelihood of your thermal scheme having a flow-to-surface event? No one wants one of these. How do you prove to the regulator that you're taking reasonable efforts to prevent it?

What's the likelihood of your thermal scheme having a flow-to-surface event? No one wants one of these. How do you prove to the regulator that you're taking reasonable efforts to prevent it?

Without AppIntel, how to you keep abreast of your competitors' regulatory battles?

How do you succeed with the regulator without reinventing the wheel?

How do you leverage others' regulatory successes and failures for your own properties?

One operator has identified subsurface geological faults within his thermal bitumen scheme. These faults are conducting steam out of his formation and into other strata. Hoping to avoid flow-to-surface problems experienced by other operators, he has implemented a plan to detect, prevent and respond to steam out-of-formation events.

Help yourself to the pertinent application pages through our self-serve, secure check out.

Get details of this cool tech Subscribers get them for freeLeveraging your competitors' regulatory battles

Would you like to have the same regulatory approval as your competitor? When I ask this question, most operators say . "No. We want better!"

How do you know your competitor's approval without reviewing her applications and approvals?

?subject=Help me review new thermal bitumen regulations&body=Help me reviewing new thermal bitumen regulations%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We keep abreast of all the new thermal regulations.

AppIntel is the quickest and easiest way to find the regulatory approvals on monitoring wells or maximum operating pressure or abandon non-thermal wells. Just type it in AppIntel's natural language search bar.

Mitigating flow-to-surface

As you know, one operator's field was the intense scrutiny of the regulator because of flow-to-surface events. It attracted at least three studies costing over $1 million.

In the end, the operator wasn't charged. The regulator decided that the operator had not done anything against the law. The operator had lived up to his commitments with the regulator.

Can you prove that you are living up to your regulatory commitments?

If you don't yet have a compliance index, you're behind the industry. Several other operators already have one.

A compliance index is a database of all the commitments you're made to the regulator in applications and supplemental information requests. If the regulator pursues you, a compliance index can show them that your operations are within the bounds they've set.

Proven completes these indexes for the industry. Because we have all the regulatory documents, we can quickly create your compliance commitment database.

?subject=Help me prove compliance to the regulator&body=Help me prove compliance to the regulator.%0D%0AHelp me start a compliance index.%0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0AType of applications:__%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Call Proven to start a compliance index.

Regulatory applications related to flow to surface

Here are ten applications and approvals related to flow to surface. It's not an exhaustive list. But through them you can see how other operators are dealing with the issue.

1. The regulator decides this operator is not at fault

1. The regulator decides this operator is not at fault

Primrose had five reported locations where bitumen emulsion flowed to surface. The flows were not restricted to old wellbores but also seeped through poor cap rock seal due to natural and induced fractures. Mostly the AER blames salt dissolution under the bitumen formation for weakening upper strata.

In their briefing to the media, the AER said that CNR had been operating within their approval limits and the company has not been charged. However, injection restrictions were placed on some areas of Primrose.

2. Where do you need lower MOP?

2. Where do you need lower MOP?

If there are areas in a scheme that demand lower injection pressures, it stands to reason that there are likely areas where a higher steaming pressure is justified.

That's how one operator viewed the MOP problem.

3. Managing MOP

3. Managing MOP

Soon after the AER's announcement of their study and decision about flow to surface, this operator decided to increase maximum operation pressure. He discusses differing pressures in several risk zones.

Surface heaves in steam operations are a given -- the AER doesn't seem concerned with that phenomenon.

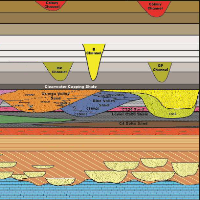

4. A geological assessment of flow to surface

4. A geological assessment of flow to surface

After the AER's recent decisions regarding steaming and flow to surface, this operator has proposed a steam strategy -- and the regulator approved it. As expected, the strategy involves risk assessment of existing and abandoned wells. But in addition it considers geology, steam volumes and schedule, surveillance reaction protocols and remediation of high risk wells. Surveillance includes monitoring wells at several formations of decreasing depth.

?subject=I want just a few email alerts&body=Sign me up for a few email area alerts. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:___%0D%0A%0D%0AType of applications___%0D%0ACentered on this UWI___%0D%0ARadius proximity from there___%0D%0A%0D%0APricing: www.appintel.info/just-alerts/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to buy just a few cheap and cheery email alerts.

5. The regulator decides this operator is not at fault

5. The regulator decides this operator is not at fault

One operator proposed carefully increasing operating pressure in some areas of his thermal scheme. He proposed several mitigation strategies including surveillance wells. This use of observation wells is starting to grow in the industry.

6. Using seismic technology to detect potential problems

6. Using seismic technology to detect potential problems

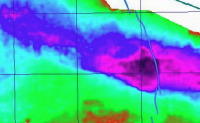

The operator of this huff and puff project is using passive seismic systems to monitor casing failures. He hopes to identify any possible failures early to prevent flow to surface.

He includes a discussion of his technical and economic review to decide which pads should be monitored with passive seismic.

7. Using the Formation Expansion Index

7. Using the Formation Expansion Index

The industry wants to know: How do you prevent flow to surface associated with surface uplift. The application contains a discussion of FEI (Formation Expansion Index) as a predictive indicator of when surface uplift might occur. It discusses the interplay of this with an associated gas cap.

Great reading for those who want to avoid such a flow.

8. Flow to surface behind pipe

8. Flow to surface behind pipe

How do you evaluate the risk of flow to surface behind pipe? This application breaks down risk assessment into geological factors and wellbore factors. Both are discussed in detail.

A plan to gently steam taking these risks into account includes his steam schedule and wellhead injection pressures. He also discusses the early detection any trouble signs.

9. Disposal wells are more difficult to get approved

9. Disposal wells are more difficult to get approved

New regulations make it harder than ever to get disposal and injection approved. The AER now requires applicants review every abandoned well near a new disposal/injector well. The AER wants applicants to ensure that each well has been properly abandoned. This regulatory fall out is partly due to the flow-to-surface problems at Primrose.

The new "checking abandonment" rule caught one applicant by surprise.

10. Disposal wells are more difficult to get approved

10. Disposal wells are more difficult to get approved

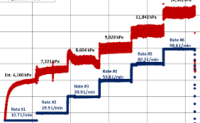

If you're wondering what you need to submit in support for a maximum well head injection pressure (MWHIP) increase, you'll want to look at this application. More than any other regulatory document, it traces the AER's process in determining maximum well head injection pressure from a step rate test.

MWHIP became a very big issue over the last few years when oil came bubbling to the surface in the cold lake area. Since that time, the march toward stiffer regulation of MWHIP has been steady.

We've given you ten applications and approvals that refer to flow to surface and its impact on the regulatory landscape. But as a bonus, here's one more. My cockney friend would be cheery if I told you that this one is legs-eleven.

11. Flow to surface has shifted the regulatory paradigm

11. Flow to surface has shifted the regulatory paradigm

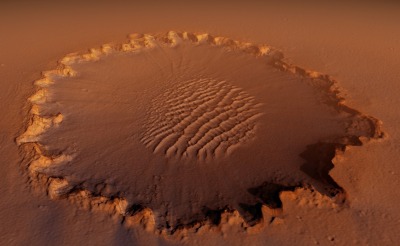

One operator's application for a new thermal scheme was met with a request for information about cap rock faulting. The regulator requested 3-D seismic interpretation and other evidence.

Such a burden of evidence would not likely have been requested 5 years ago. But, because of recent flow to surface problems, the regulator has become extra sensitive to such issues.

?subject=I want a cheap and cheery one day trial of AppIntel to search for ASP schemes&body=Sign me up fro a one day AppIntel trial so I can to search for ASP schemes.%0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0APricing: www.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now for a one day trial.

Tags: Seismic, Thermal, Compliance, Heavy Oil

Granger Low 22 Apr 2017

Granger Low 22 Apr 2017

Don't blow the lid

Fracking into a neighboring well causes a blowout

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Three corner shots

Can you find them?

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

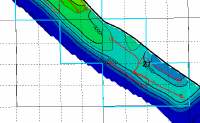

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Celebrating 2025, a year of innovation

Oil and gas paradigm shifts this year

RTF: Most refused submission type in November

Leading indicators from industry

Astrobleme impacts deep well disposal scheme

Learn from the experience of other operators

Non-meridian thermal wells

Still drilling horizontal wells N‑S? Why?

Steam surfactant co-injection

Want to win? What is your competitive advantage?

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share