Battle for the future of bitumen recovery

Methane or Propane?

Battle for the future of bitumen recovery Methane or Propane? What is the future of bitumen recovery? Primary or thermal? SAGD or CSS? Inject methane, propane or surfactant?

Battle for the future of bitumen recovery Methane or Propane? What is the future of bitumen recovery? Primary or thermal? SAGD or CSS? Inject methane, propane or surfactant?

Which of these will prove to be the most cost effective recovery tool for bitumen? Some operators are experimenting with each in the same field.

All these have been passed the theoretical phase and lab test phase. Each has been implemented in the field.

?subject=Help me with solvent SAGD best practices&body=Please help me with solvent SAGD best practices. %0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We stay on top of best practices from applications.

Primary recovery

Some operators are falling back to primary recovery upon deciding that enhanced recovery isn't economic. For the right bitumen viscosity, some operators are able to produce oil without any injectant.

Progressive Cavity Pumps (PCP) are often used for primary recovery. Primary bitumen production usually produces 3-5% recovery, but some installations claim up to 12%.

Sometimes sand is produced with the bitumen. Using Cold Flow or Cold Heavy Oil Production with Sand (CHOPS) up to 50% of the production can be sand.

Just add steam

Steam, soak, suck it back. Cyclical Steam Stimulation (CSS) or "huff and puff" introduces steam into a bitumen reservoir as a stimulation treatment.

Recently many operators have been using horizontal wells in their CSS schemes.

?subject=Help me with CSS best practices&body=Please help me with CSS best practices. %0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We stay on top of best practices from applications.

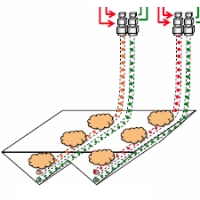

Steam Assisted Gravity Drainage

SAGD has become very popular. Rather than injecting and producing from the same well bore as in CSS, a horizontal injector is placed very near a horizontal producer.

Steam injected melts the bitumen which is produced by the producing well.

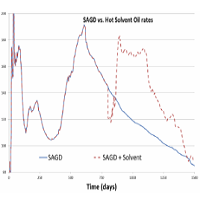

Steam Additive - Methane

In addition to steam, some operators are adding methane. Since methane doesn't condense at reservoir conditions, it helps maintain injection volume introduced by the steam. Steam rate can be reduced and production still stays high.

In addition to steam, some operators are adding methane. Since methane doesn't condense at reservoir conditions, it helps maintain injection volume introduced by the steam. Steam rate can be reduced and production still stays high.

Methane injection can reduce the cost of steam injection, one of the largest operating costs of SAGD.

Methane injection has become very popular with SAGD operators, but very few CSS operators are trying it.

Steam and Propane co-injection

One operator is a proponent for injecting propane into his thermal operation. On top of saving steam generation costs, water processing and disposal costs, he believes he will generate 25% more bitumen recovery.

One operator is a proponent for injecting propane into his thermal operation. On top of saving steam generation costs, water processing and disposal costs, he believes he will generate 25% more bitumen recovery.

And later, you can produce all your propane back for resale.

The propane injected absorbs into the bitumen and reduces viscosity. Additional recovery is the result.

You can get his application documents by clicking the below. You can get them in moments -- self serve. For less than $100.

Get details of this cool tech Subscribers get them for freeAdding surfactant

Some operators are injecting surfactant into their thermal schemes. Some hope to heal hot spots that short-circuit injector and producer paths.

Some operators are injecting surfactant into their thermal schemes. Some hope to heal hot spots that short-circuit injector and producer paths.

Other operators hope for additional recovery using surfactant.

?subject=I want a one day trial of AppIntel&body=Sign me up for a one day AppIntel trial so I can search quickly for all the solvent SAGD applications.%0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0AType of applications:___%0D%0A%0D%0APricing: https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now for a one day trial.

Granger Low 18 Oct 2016

Granger Low 18 Oct 2016

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share