10 operations take thermal to the next level

Application documents show you how

There's lots of talk in the industry about edgy thermal technology. Much more talk than actual field trial experiments.

There's lots of talk in the industry about edgy thermal technology. Much more talk than actual field trial experiments.

But which of these strategies are worth incorporating into your thermal operations?

If you implement new technology wisely, it can take your operation to the next level. If you do it wrong, you might go broke. You need to learn what others have already tried and measure their success and failure.

Taking thermal technology to the next level in the field is risky. No matter how many calculations you do; no matter how lab tests you conduct; implementing in the field will always bring surprises.

Look back at others' operations

It makes sense to see what others have done in the field. A field "look back" needs to consider the operator's intentions and their actual results.

The best way to conduct a look back is to read the application documents of others.

These documents show their intentions and promises to the regulator.

?subject=Help me review new thermal bitumen recovery technology&body=Help me reviewing new thermal bitumen recovery technology%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We keep abreast of all the new thermal technology.

They also indicate the actual UWI locations of the proposed operation. Using these locations, you can review injection and production history and draw your own conclusions about success or failure of the field trial.

Ever wonder how edgy thermal technology worked in the field? You can find out by reviewing these ten applications by other operators. Just follow the links to get their application documents.

1. Forget steam. Use microwaves.

1. Forget steam. Use microwaves.

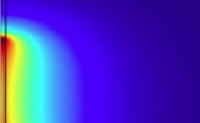

One operator has tried heating with radio waves. Similar to the principle of microwave oven heating, he's introducing radio waves into a formation and expects elevated temperatures.

If you'd like to try putting your bitumen bearing formation in a microwave oven, check out his application.

2. Electrical heating

2. Electrical heating

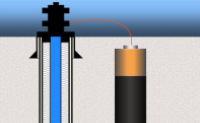

What if you could heat a heavy oil zone directly with electricity? Brings visions of just hooking into the electrical grid and saving a lot of capital cost.

One operator proposed using leads strung down the well to get the heating elements to depth. He used these to heat water in-situ.

3. Heating with casing conduction

3. Heating with casing conduction

What if you could heat a heavy oil zone without injecting any steam? Think of the capital cost you could save by skipping the boilers.

This operator proposes to heat a bitumen zone using electrical current. He's using the casing as the conductor.

4. Electricity heating and solvent

4. Electricity heating and solvent

One operator is implementing a C5+ solvent soak with his electro-thermal heating scheme. His application documents include the well location where he is testing this technology so you can watch the production spike during his test.

5. Making steam with produced water

5. Making steam with produced water

One operator made a boiler than can handle produced water. His approved application shows cost cutting arguments for using such equipment.

?subject=Help me get up to speed on new thermal projects.&body=Help me get up to speed on new thermal projects.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We watch the leading indicators of the industry.

6. Injecting Alkali in SAGD

6. Injecting Alkali in SAGD

This operator is testing several alkali compositions and concentrations. Alkali may react with organic acids in the reservoir to generate surfactant in-situ. The resulting surfactant should reduce interfacial tension and allow oil droplets to be more mobile in the reservoir.

7. Injecting bugs in SAGD

7. Injecting bugs in SAGD

Yet another operator is using microbes in some SAGD pad startup procedures. In the application, he discusses corrosion, formation and perforation plugging, microbe population control and several other issues.

8. SAGD and CSS meet

8. SAGD and CSS meet

One operator is injecting noncondensable gas injection in a SAGD pair and adding infill producers with a twist. The infill producers are operated on a cyclic steam huff and puff.

9. Temporarily abandoning a SAGD operation

9. Temporarily abandoning a SAGD operation

One operator has decided to temporarily suspend operations. His SAGD scheme is taking a sabbatical. Check out his thoughts about how his scheme will recover when oil prices improve.

10. Toe to heel air injection

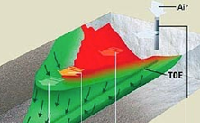

10. Toe to heel air injection

Another operator says that the toe-to-heel air injection (THAI) process failed in his pilot. He discusses the process, why he believed it failed, and what he'll try next.

?subject=I want an expert to help for the same price as an EIT&body=Tell me more about getting expert help for the same price as an EIT.%0D%0A%0D%0AMy Name_______%0D%0A%0D%0AMy Phone_______%0D%0Aor call Proven at 403 803 2500.">Contact Proven for expert work on the cheap.

We've given you 10 edgy technologies to review, but there are many more. In fact, here's one more interesting technology to help image steam chambers...

And one bonus...

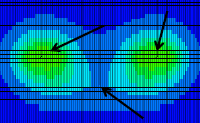

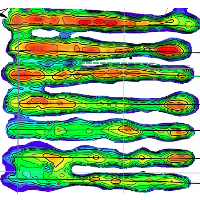

11. Four-D Seismic delineates steam chamber

11. Four-D Seismic delineates steam chamber

This operator included a discussion of 4D seismic technique and interpretation. He believes that 4D seismic images a steam chamber and helps confirm the bitumen thickness. He says a 4D seismic anomaly is created with the oil sand is heated to 60 degrees C.

We've given you references to 10 edgy thermal technologies -- and one bonus technology. This is more than cool technology. Some of these could drastically improve your thermal scheme.

You owe it to yourself and your investors to read the application documents that explore these pilot projects. You decide whether they will work for your field.

You can help yourself to their application documents by using our self serve, secure check out. Follow the links above to buy these documents now.

All these have been passed the theoretical phase and lab test phase. Each has been implemented in the field.

Each have been ground truthed with injector UWIs. You can read their application, then check out the actual results by looking at their patterns in Accumap.

?subject=I want a one day trial of AppIntel to research applications like mine&body=Sign me up for a one day AppIntel trial so I can check out thermal applications like mine. I want to to see their technology.%0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0AType of applications:___%0D%0A%0D%0APricing: https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to try it cheap and cheery.

Tags: Thermal, Heavy Oil

Granger Low 20 Mar 2017

Granger Low 20 Mar 2017

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Celebrating 2025, a year of innovation

Oil and gas paradigm shifts this year

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share