Surprise! Sour gas production from a sweet thermal scheme

Dealing with surprises in the oil and gas industry. What to do next.

In the oil industry, operations do not always occur as expected. From unexpected well flow rates to processing facility upsets -- surprises abound.

In the oil industry, operations do not always occur as expected. From unexpected well flow rates to processing facility upsets -- surprises abound.

Knowing how other operators dealt with

those surprises can reassure and help you reorganize

Without AppIntel AI, how would you know how to deal with the surprises? How would you find out how others managed?

Textbooks and technical papers will not help. They don't deal with surprises.

Simulations cant help with the unexpected. They only quantify what you already know.

Only AppIntel AI gives you insight into the surprises of other operators and how they mitigated.

After first steam, one operator found that hydrogen sulphide production started to produce from a sweet heavy oil play. It changed every one of his operational paradigms. Surprised and perplexed, he also rushed to add a sulphur recovery unit. See his efforts to rebalance his operation including his emergency procedures.

Get details of this cool tech Subscribers get them for freeSo, how do you handle those surprises that pop up out of nowhere? Why go through all the trouble of starting from scratch when you don't have to?

The truth is, its even better to stay ahead of the curve rather than just react when something unexpected happens. With AppIntel AI, you can spot potential issues before they arise and get ready with a plan. Plus, every detail is thoroughly checked by a tough regulator — so you know you're getting top-notch strategies that actually work.

Here are a few examples of operators disclosing the unexpected and how they mitigated.

Steam operation blow down

Steam operation blow down

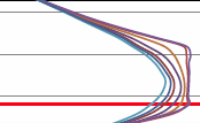

You can leverage the experience of other steam operators. Like the explanation of the unexpected results this operator found during steam recovery blowdown testing.

Understanding of recovery and flow rates during blowdown is critical to understanding reserves forecasting as well as long-term pipeline and facilities management.

Polymer result disappointment

Polymer result disappointment

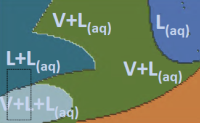

One operator claims to have started the very first polymer flood in Canada. Now she proposes to end ASP injection in one of her big floods.

In her application, she conducted a "look-back" to determine the success of the flood. It was a bit disappointing. By reading her submisison, you can see how well her scheme performed compared to expectations. She discloses the pore volumes of chemical injected through the system and the results. She also makes mention of the economic viability of the flood.

Gas injection surprise

Gas injection surprise

For gravity stable gas floods, chase gas usually stays at the top of the structure. But for other types of floods, injected gas might end up in a place you least expect. The more you inject, the more you learn.

Even better than learning from your own mistakes, is learning from the mistakes of others. There are dozens of pools that are injecting gas in the province. Many have been injecting for 5-30 years. Looking at their floods will help you learn more about the benefits and pitfalls of immiscible gas injection.

Underwhelming thermal performance

Underwhelming thermal performance

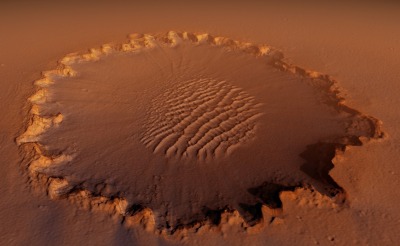

SAGD and other thermal bitumen technologies have performed poorer than expected. Thermal recovery has performed well, but not as well as we all hoped. This is one of the reasons that Shell, ConocoPhillips, Statoil, ExxonMobil, Marathon, Koch and Imperial have all abandoned their Western Canada bitumen assets selling them to local Canadian operators.

How do you deal with the unexpected? Why re-invent the wheel?

Even better than dealing with surprises as they come, using AppIntel AI can help you anticipate the unexpected and plan ahead. Each disclosure is vetted by a picky regulator — you can trust the best tactics are employed.

?subject=Help me learn more about microbial flooding&body=Please help me learn more about microbial flooding. %0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for help on learning about microbial failures and successes from applications.

Tags: Polymer, Gas Injection, Flood, Thermal, Facilities

Granger Low 24 Nov 2025

Granger Low 24 Nov 2025

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share