Forgot to take care of that flood?

Schedule these 12 activities every year.

A water flood can add reserves very cheaply. But how do you remember to take care of yearly maintenance to get the best performance?

A water flood can add reserves very cheaply. But how do you remember to take care of yearly maintenance to get the best performance?

This blog post is brought to you by Proven Reserves Exploitation Ltd., one of our technology partners.

AppIntel is the quickest and easiest way to find information on water flood or ASP or miscible flood. Just type your search terms in AppIntel's natural language search bar to see all the technical information included in the regulatory approvals.

One operator has an ASP flood that hasn't been maintained for over 6 years. When you ignore a flood for that long, gas-oil ratio spikes, water cut gets out of control, oil rate drops and reserve bookings must be written down.

You can see her last maintenance in an application from many years ago through our self-serve, secure check out.

Get details of this cool tech Subscribers get them for freeTips for maintaining floods

Flood maintenance does not need to be a full time job. But periodic reviews are very important. Here are some tips to consider about maintaining your flood.

1. First things first

1. First things first

If you need a refresher on flood maintenance, start first by reviewing a few metrics to determine the health of your flood. It's like taking your flood to the doctor for a check up.

Check things like the number of active injectors and the ratio of these to the number of producers.

2. Calculate VRR monthly

2. Calculate VRR monthly

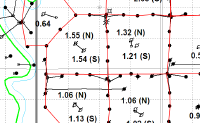

Calculate voidage replacement ratio in a monthly review. If you are going to keep up the pressure of the reservoir, you will need to know how injection is balancing production and expansion. You will also need this to make sure you are in compliance with voidage replacement regulations. Check VRR monthly -- checking yearly is too late to fix problems.

Calculating voidage is a pain. It involves importing production data and ensuring all the pressure information is up to date. For painless VRR, Proven Reserves will calculate voidage for only $300 per month and send you a monthly email with the results.

?subject=Call me about painless voidage calculation&body=Call me about painless voidage calculation for only $300 per month.%0D%0A %0D%0AMy Name:__________ %0D%0AMy Phone Number:__________">Contact Proven to get it started.

There are many VRR reporting strategies that will help you keep in compliance. They do not require a change in injection, but a change in calculation strategy. Proven can help with these.

3. Tune-up your flood to find hidden jewels

3. Tune-up your flood to find hidden jewels

Once per year, just before reserves time, tune up your flood.

Floods depreciate quickly when you do not tune them up at least yearly. Water cuts increase, production falls, reserves are stagnant or written down.

I know one flood engineer that has added over $500 million in reserve value while working on just one flood for 6 years. He added reserves every single year.

4. Review the pattern: Success is in the pattern not just the polymer

4. Review the pattern: Success is in the pattern not just the polymer

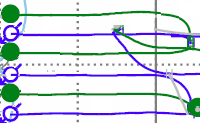

During your yearly review, consider injectant additives. But first review the injection pattern.

What aspects impact polymer flood performance? Polymer injection is not a panacea without problems. Pattern is also a prime point.

It would be nice if just picking the right injectant would create a great result. In reality, many successes are required to ensure a great polymer flood.

5. Awesome water shut off -- what joy!

5. Awesome water shut off -- what joy!

During the yearly review, look for water shut off candidates.

The prize is big for water shut-off. One source believes that our industry produces over 90% water cut.

One operator tried blocking perm streaks with colloidal dispersion gel in Pembina. He believed that polymer chemistry is a very important element of the strategy.

6. Using polymer as a diverter

6. Using polymer as a diverter

If you need water shut-off, consider several options for diverters.

Some operators have used nanospheres to divert water in a flood.

They hope that this diverter will block thief zones where water is sweeping through the reservoir from injector to producer.

?subject=Help me get more from my old flood&body=Help me tune up my old flood, improve recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for help. We add over $20 million of reserve value ninety-five percent of the time when we tune up a flood.

7. Detox your waterflood

7. Detox your waterflood

If you discover some spectacular failures in your flood, tell yourself you have learned something very valuable about the pool.

Even old floods have more to give. Operators that balance their floods yearly continually add reserves on 1960 vintage floods. Some call it flood optimization. Some call it sloshing water around.

One operator watered out a producer within months -- he had recovered less during a flood than on primary. But rather than giving up, he spent time balancing his flood pattern. In the process he discovered that directional permeability ruled his tight flood. By taking advantage of the trend, he tripled his recovery factor.

8. Benefits of flood balancing

8. Benefits of flood balancing

Make sure you rebalance your flood patterns every year during your annual review.

Rebalancing a flood is cheap to do and provide immediate benefits.

Pattern balancing a flood should be completed every year. Pattern balancing brings the quickest, easiest and cheapest reserve adds. It is one of the cheapest ways to add production.

9. Fix water flood problems with Optiflood

9. Fix water flood problems with Optiflood

If you are swamped at annual review time, have an expert use Optiflood on your pool.

You can use Optiflood to fix most water flood problems.

Optiflood is a system to collect and review production, injection and pressure information in a water flood.

?subject=Help me improve my flood using Optiflood&body=Help me improve my flood using Optiflood. I understand Optiflood is a process that incorporates learnings from improving 200 floods.%0D%0A%0D%0AMy Name ________________%0D%0AMy Phone number _____________%0D%0AField ______________%0D%0APool_______________%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for their experience at using Optiflood to improve over 200 floods.

10. Consider WAG

10. Consider WAG

During the annual review, consider alternate injection strategies like WAG.

Water-Alternating-Gas injection works well in certain conditions.

By reviewing the production history behind existing WAG floods, you can see exactly how it performed. Using that information will help you decide how to use it with your flood.

11. End of life strategies

11. End of life strategies

Do not despair if your pool is near the end of its life. Many strategies can dramatically improve production and reserves even for a depleted pool.

Note: Even if your pool on primary is near the end of its life, it is not too late to start a flood.

One operator has a mature pool that has produced without pressure support and has recovered 85% of the primary reserves.

She believes that she can add 115% more reserves by starting a water flood.

12. How everyone else meets voidage

12. How everyone else meets voidage

In your yearly review, ensure that you are in compliance with the regulations.

Sometimes all you need to do to get back into compliance is get the rules changed. Perhaps you just need an application to get you permission. You might not need to change what you're doing. It's kind of like applying to have the speed limit changed to fix a ticket.

Would it be helpful to know how other operators handle their statutory requirement to meet voidage? Reading the applications of others helps you quickly copy the successes of others.

?subject=Sign me up for an AppIntel trial for compliance&body=Sign me up for an AppIntel trial. I need to quickly find applications similar to my compliance problem.%0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0AType of applications:__%0D%0APricing: https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us for a one day trial of AppIntel search.

We have given you twelve tips to help you remember the maintenance tasks for a flood. And here are two bonus tips.

13. Every time you submit to the regulator

13. Every time you submit to the regulator

Do not forget to get a new pressure taken on your flood in your yearly review.

And almost every time you review your flood, you will need an application to the regulator.

Every time you submit to the regulator, remember to protect yourself using a few inside tips. They will help ensure your application is approved and will protect you from giving away too much information. Contact Proven to help you stick handle through the regulations.

14. Checking maintenance on potential acquisitions

14. Checking maintenance on potential acquisitions

Upside and downside. Isn't that what you're looking for when you evaluate an acquisition target?

If the flood has not been maintained for several years, that's a definite downside. One quick way to check is to put your acquisition through the test in Tip 1 above.

In conclusion

We have given you twelve tips (and two bonus tips) to help you with the maintenance tasks for your flood. Call Proven to help you maintain your flood. We are flood experts -- we have worked on over 200 floods.

AppIntel Advantage 88: Quick copy of the best flood optimization practices.

Use AppIntel to find the best practices for optimizing your companys oil pools.

Turn the technical debt of your legacy pools into increased cash flow.

Tags: AER application, Polymer, Flood, Compliance

Granger Low 22 Dec 2023

Granger Low 22 Dec 2023

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Celebrating 2025, a year of innovation

Oil and gas paradigm shifts this year

RTF: Most refused submission type in November

Leading indicators from industry

Astrobleme impacts deep well disposal scheme

Learn from the experience of other operators

Non-meridian thermal wells

Still drilling horizontal wells N‑S? Why?

Steam surfactant co-injection

Want to win? What is your competitive advantage?

Surprise! Sour gas production from a sweet thermal scheme

Dealing with surprises in the oil and gas industry. What to do next.

10 ways to increase production before Christmas - Infographic

For your wall to remind you

10 ways to increase production before Christmas

Each cost less than half a million

Using AI to reduce risk of oil and gas failure

How can you assess the risk without knowing the epic fails?

Artificial intelligence using vetted oil and gas information

Using anything else is dangerous

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share