Safer than self-driving cars

Blending down H2S content

Self-driving cars seem to be on the horizon and many debate their safety. The oil industry has much stricter safety protocols in dealing with sour gas pipeline specifications.

Self-driving cars seem to be on the horizon and many debate their safety. The oil industry has much stricter safety protocols in dealing with sour gas pipeline specifications.

Without AppIntel, how would you find novel approaches to facility design? We found this one by typing into the AppIntel search box acid gas blend .

Self driving car photo credits: Becky Stern. You can share it too.

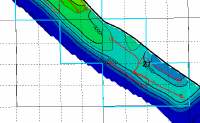

One operator is blending acid gas with a sweeter stream to keep under the gathering system specification. The entire stream is sent on to a Sulphur processing facility.

Help yourself to his application documents from our self-serve site.

Get details of this cool tech Subscribers get them for free?subject=Sign me up for an AppIntel subscription&body=Sign me up for an AppIntel subscription so I can get all the new facility applications. %0D%0AHelp me get them within moments rather than waiting for weeks from and regulator.%0D%0A%0D%0AMy name _________%0D%0AMy phone number _________%0D%0APricing: https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or, if your need is urgent, call AppIntel Sales at 403 803 2500)">Contact us about an AppIntel subscription.

Self driving cars

Driverless cars have captured the imagination of North America. Proponents dream of the disappearance of road rage and lower accident rates. Opponents believe that such cars erode human freedom of expression.

Bugs still exist in the prototypes. Driverless collisions make national news. Safety protocols are still evolving.

Oil industry is safer

The same dreamers that excite over horse-less and driver-less carriages, proclaim nightmares about the oil and gas extraction industry. They twist their hands over potential pipeline ruptures and marine oil spills.

But there are far more miles of pipeline in Alberta than miles of road. And also there are far fewer pipeline leaks than auto accidents.

Regulators and facility engineers make a much more concerted effort to protect the public than vehicle operators.

Pipeline H2S content regulated

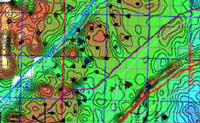

Hydrogen sulphide content of Alberta pipelines is strictly regulated. A pipeline designed to carry 5% H2S is not allowed to carry any more than that fraction.

So when high H2S content wells are discovered in a sweet pipeline area, operators tend to blend. Ten percent H2S is blended with sweet gas until it is within the gathering system specification. Safeguards are put in place to ensure compliance.

The subject application discusses safeguards for this installation. The regulator required them and the operator responded willingly.

AppIntel hit alerts deliver applications of technical interest

A hit alert automatically sends you new AER applications that match a search string. Get hit alerts for applications that contain acid gas blend or Kawka gas somewhere in the application documents.

Every day AppIntel searches through all newly submitted documents for your search string. When it finds an application that meet your criteria, you receive it in your email inbox.

?subject=I want to see applications delivered in moments, not weeks.&body=I want to see closed applications delivered in moments, not weeks.%0D%0A%0D%0AApplication Number:___%0D%0AMy Name:___%0D%0AMy Phone Number:___%0D%0A%0D%0Ahttps://www1.appintel.info/order-application-on-demand/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to try it out.

Tags: Gas Injection, Compliance, Facilities

Granger Low 16 Jul 2018

Granger Low 16 Jul 2018

Don't blow the lid

Fracking into a neighboring well causes a blowout

Continuing Canadian thermal innovation doubled oil production

Experimental Propane Solvent co-injection in thermal

Shale in SAGD

How much is too much? Ask AppIntel AI.

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI shows SAGD type logs

Check out the picks and cap rock

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share