SAGD threat turned into opportunity

Upping MOP in a thermal scheme

If there are areas in a scheme that demand lower injection pressures, it stands to reason that there are likely areas where a higher steaming pressure is justified.

If there are areas in a scheme that demand lower injection pressures, it stands to reason that there are likely areas where a higher steaming pressure is justified.

That's how one operator viewed the MOP problem. She conducted extensive research and found an area of her scheme that has outstanding cap rock integrity. Based on her findings, she proposed to increase MOP by 10% in that area. You can get her application documents within moments through our self serve secure checkout.

Get details of this cool tech Subscribers get them for free?subject=Help me get up to speed on MOP advances in SAGD&body=Help me get up to speed on MOP advances in SAGD. Show me different operator's opinions from their applications.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for recent developments. We stay on top of thermal recovery strategies.

AER decisions after recent flow to surface events have defined areas where lower steaming pressure is required. Some of those areas have severe restrictions on maximum operating pressure (MOP) of the scheme. In some areas, steam can only be injected at hydrostatic pressure.

But it seems likely that some areas might stand a higher steaming pressure. Most operators believe that more steam injection at a higher pressure will bring better bitumen recovery.

This application includes one of the most interesting treatment of caprock integrity ever seen in the literature. It includes over 75 seismic and other geoscientific figures complete with descriptions of the scientific framework for the analyses.

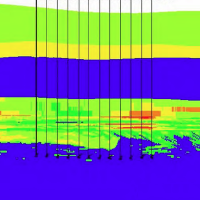

Included are many geophysical analyses including structure, isochron, natural fracturing, temperature considerations and attribute analysis. For example, the spatial variation of Poisson's ratio and Young's modulus (as featured here).

The operator considered many facets of caprock integrity including channels incised into the caprock, salt dissolution and existing faulting.

Stay up to date on SAGD advances by email alert

Imagine if you could get an email alert every time a new SAGD application was submitted. You could use those alerts to stay abreast of new developments like this one. You can get unlimited alerts using AppIntel.

?subject=I want just a few email alerts&body=Sign me up for a few email area alerts. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:___%0D%0A%0D%0AType of applications___%0D%0ACentered on this UWI___%0D%0ARadius proximity from there___%0D%0A%0D%0APricing: www.appintel.info/just-alerts/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to buy just a few cheap and cheery email alerts.

Tags: Thermal, Heavy Oil

Granger Low 20 Sep 2016

Granger Low 20 Sep 2016

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share