Lessons learned from water flooding the Montney

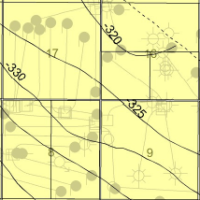

Beware this injection pattern

Although drilling the Montney has been popular for over five years now, few operators have tried to flood it. Concerns about low permeability, poor injectivity, small drainage areas, and poor inter-well connection have caused them steer clear of secondary recovery.

Although drilling the Montney has been popular for over five years now, few operators have tried to flood it. Concerns about low permeability, poor injectivity, small drainage areas, and poor inter-well connection have caused them steer clear of secondary recovery.

But one operator explains the results of his pilot flood of the Montney and describes his learnings in a recent application. Some areas of his pilot experienced very quick recycle short-circuit paths through the reservoir.

He has since decided against a gravity stable water flood but has found other injection patterns beneficial. In the end, he may have spent $16 million in drilling and completion capital that wasn't required. We found this information using AppIntel.

Get his application documents using our self-serve portal.

Get details of this cool tech Subscribers get them for free?subject=Help me find all the Montney flood applications&body=Sign me up for a one day AppIntel trial so I can find all the Montney flood applications. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:___%0D%0A%0D%0APricing: https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now for a one day trial.

You'll want to read his application so you can capitalize on his learnings and avoid his mistakes. By reviewing the lessons he learned, you can avoid spending the kind of capital he found detrimental to recovery.

Flood lessons learned

"Those that fail to learn from history, are doomed to repeat it." (Winston Churchill)

This operator learned at least four lessons in this flood.

In flooding most thin beds, the structure gradient must be considered before initiating an injection pattern. Failing to do so may water out producers permaturely and reduce recovery.

Although it appears to be a good idea, don't try to use a water injector as a fence to keep a gas cap pressurized. It's likely to fail at segregating a gas cap and reduce recovery of up-dip oil wells.

We have seen so many horizontal to horizontal injection patterns fail. Many such patterns don't consider that the geological variability along a horizontal well may create short circuits for water injection.

Fracture orientation should be understood before even drilling primary wells especially if they will be horizontal multi-fractured wells. If fracture orientation is not considered during initial primary drilling, it should at least be considered before flooding. Natural and induced fractures create super highways of injection short circuiting.

?subject=Help me get up to speed on flooding the Montney&body=Help me get up to speed on flooding the Montney%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for recent intelligence on Montney floods.

Tags: Tight, Flood

14 Dec 2020

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share