The joy of awesome water shut-off

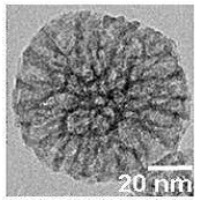

Blocking water with colloidal dispersion gel

How do you shut off water production without reducing oil rate? Many have tried. Some have succeeded.

How do you shut off water production without reducing oil rate? Many have tried. Some have succeeded.

One operator tried blocking perm streaks with colloidal dispersion gel in Pembina. He believed that polymer chemistry is a very important element of the strategy.

His gel is designed to block water -- not at the well bore, but deeper in the formation. He maintains his gel has five times the resistance to water flow than straight polymer.

?subject=Help me get up to speed on polymer flooding&body=Help me get up to speed on polymer flooding%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We have all the details from all the installations.

You can see the design details of his pilot documented in his application to the regulator. If you're interested in trying something similar, you'll want to read his application documents. You'll find:

- his beliefs about polymer design

- importance of additives

- lab testing of the injection scenario

- injection pattern design

- injection schedule

- injectant slug size

- PVT of the reservoir fluids

- reservoir pressure

- surface equipment installation

Help yourself to his application documents through our secure checkout.

Get details of this cool tech Subscribers get them for freeBig prize

The prize is big for water shut-off. One source believes that our industry produces over 90% water cut.

Water handling is the single biggest cost to the industry. Water lift, water separation, water storage, water treatment, and water pumping cost billions in op cost dollars every year.

Check out the results

Since the application was submitted several years ago, you can review the results of his pilot. He included the actual wellids of the treated wells in his application. You can check out his production results in Accumap.

Textbooks and classes may help you understand a bit about polymer injection. But if you really want to understand how they perform in the field, you must read the polymer applications documents. They report progress on polymer floods to the regulator. Each application is ground truthed to actual UWIs. Each application is adjudicated by a picky regulator.

?subject=Polymer Flooding: State of the Art Seminar&body=Send me information about the seminar %0D%0APolymer Flooding: State of the Art. %0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________%0D%0A%0D%0A(Or call Proven Seminars at 403-803-2500.)">Contact Proven about the seminar "Polymer Flooding: State of the Art" in the week of the 20th.

A long line of successes required

It would be nice if just picking the right injectant would create a great result. In reality, many successes are required to ensure a great polymer flood.

Obvious flood elements are picking an injectant and picking an injector, But there are many other very important, but often overlooked, elements that will promote a successful flood. Here are a few you may not have thought about.

Injectant compatibility. The phase behavior of the entire system is very important. Injectant combined with crude oil combined with reservoir water combined with mineralogy sometimes produces some unpleasant results. You want to find those before plugging off an injector.

Permeability. Directional permeability is a key factor to flood success. Many floods have been destroyed because permeability direction was ignored.

Pattern. A useful injection pattern that promotes good sweep is absolutely essential. You must get water into the right places in a reservoir or the flood will fail.

Pattern pressure. Average pressure for a pool is only a weak measure of potential. Each pattern has a pressure. Some patterns will be woefully shy of pressure.

Pattern maintenance. At least yearly you must review the chosen pattern and re-balance the injection volumes. These get out of balance very quickly. Soon you'll find you're injecting too much water in the wrong places.

?subject=I want a cheap and cheery one day trial of AppIntel&body=Sign me up for a one day AppIntel trial so I can check out polymer schemes. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0APricing: www.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to try it out Search for all the polymer schemes.

Tags: Polymer, Flood

Granger Low 30 Mar 2017

Granger Low 30 Mar 2017

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share