5 ways your flood is trying to get your attention

Are you listening? Take the quiz.

This post is brought to you by one of our information partners, Proven Reserves Exploitation Ltd.

This post is brought to you by one of our information partners, Proven Reserves Exploitation Ltd.

What is your water flood trying to say to you? If it could speak, what would it tell you it needs?

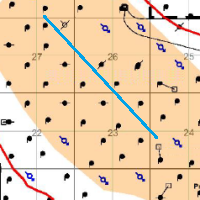

One operator has a water flood that has been functioning for over 50 years. She listened to her flood.

The flood has had injection from the periphery and now she is proposing a few additional injectors in the middle of the sweet spot. As she changes the sweep, she is sure to recover previously unswept oil.

You can see her efforts in her application documents within moments by clicking the button below

Get details of this cool tech Subscribers get them for freeYou might call this sloshing water to and fro. Usually, every time you change water sweep direction, you increase recovery.

Although the language of floods is complex, you don't really need a reservoir simulator to communicate with it. Here's a crash course in talking the talk. (We're not even going to do anything complex like calculate voidage replacement ratio yet.)

Check out an infographic along the same subject lines.

?subject=I want an expert to help for the same price as an EIT&body=Tell me more about getting expert help for the same price as an EIT.%0D%0A%0D%0AMy Name_______%0D%0A%0D%0AMy Phone_______%0D%0Aor call Proven at 403 803 2500.">Contact Proven for expert work on the cheap.

Five ways to hear what your flood is trying to say to you.

1. High producer to injector ratio

To check this, count the number of producers in your flood. Then check the number of producers directly offsetting your injectors. Then divide by the number of injectors.

A. Number of producers in flood ____________

B. Number of producers offsetting the injectors ______________

C. Number of injectors____________

D. A/C= __________

E. B/C= __________

If your ratio of producers to injector is more than 4, you're probably getting very poor support. It's hard to get enough water into a flood with very few injectors.

2. Less than 90% of your injectors are active

To check this, count the number of suspended injectors. Count the number of active injectors.

F. Number of active injectors ____________

G. Number of suspended injectors _____________

H. F/(F+G) ___________

If your active injector ratio is less than 90%, chances are that your water is not going to the right patterns.

You might also have injector plugging problems. Injectors can plug because of fluid compatibility issues. They could also plug if the water is swelling clays in the formation.

Suspended injectors might also be victims of broken injection lines and pumps.

?subject=Help me improve injectivity.&body=Help me improve injectivity, increase sweep, increase recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We can find ways to improve injectivity.

Whatever the cause, an low active injector ratio means water is not getting where it's needed. Likely the patterns around the suspended injectors are receiving poor support and getting poor sweep. That all tallies up to poor reserve recovery in the pattern.

3. One well is taking more than 20% of the injectant

Record the injection volumes into all the injectors last month. Sort the list of injectors by their injection volumes. How much of the volume is going to the top three injectors?

Top three injectors:

| Fraction of field injection | last month injection volume | UWI |

|

|---|---|---|---|

| J. (top) | |||

| K. | |||

| L. |

Many floods have most of the water in the field going to the top three injectors. This happens because operators need to put away produced water but let it go where its easiest to inject. If an injector goes down due to a well, line or pump problem, the additional water gets shunted somewhere else.

Patterns near the remainder of the injectors will be under injected. Although the voidage replacement ratio (VRR) of the flood may be compliant, it's very likely that the VRR of individual patterns may vary by as much as 10 times. You may find you're recycling a lot of water in a few patterns, but most of the patterns are getting a very poor performance.

4. Pressure is declining

Find the original pressure of the pool. Now check your last recorded pressure.

M. Original pressure ___________

N. Bubble point pressure ___________

P. Current pressure ___________

Q. P/N __________

If the current pressure is less than original and also less than bubble point pressure, then productivity is way down.

Although we've seen floods work with reservoir pressures as low as 1 MPa, the production of the pool is far less than its potential.

You can add significant value to the flood by increasing injection and reservoir pressure.

5. No new injectors in the past 3 years

Find your most recent injector. When did it start?

R. Years since start of your most recent injector ____________

If you're started no new injectors over the last several years, then water cut of your flood is likely sky high. Changing injector locations almost always improves sweep, recovery and oil cut. Starting a new injector lets water sweep through new paths and pushes oil out of new rock crannies.

Many operators are adding injectors to their floods. Improving water flood performance adds production and reserves. If you're careful, floods can be optimized to recover new reserves for six decades.

Every time you change the sweep pattern, you're likely to get more reserves and oil production. Proven once helped a company drill a new infill that produced 20 bopd of clean oil in an otherwise watered out flood.

?subject=Help me balance my injection patterns&body=Help me balance my injection patterns, increase sweep, increase recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We can predict the extra reserves.

Sum it all up -- what's the opportunity?

To do a quick evaluation, let's use this information you've collected to conduct a short quiz.

S. E/4_____

T. 0.9/H_____

U. J/0.2_____

V. 1/Q_____

W. R/3_____

X. S x T x U x V x W ____________

What does it all mean?

If X is less than 5,

Congratulations! You are right on top of your flood. You're listening to your flood and it's paying you in spades. Your flood sparkles with optimization. You talk the talk and you're walking the walk. Give yourself a high five and ask for a bonus.

If X is between 5 and 20,

Time for some fine tuning. You're listening but you have some room for improvement. Listening to your flood a bit better will bring you more recovery and more cash flow. Look for a few ways to improve your flood. Call the flood tune up experts at Proven. Most of the flood improvement ideas are very cheap.

If X is between 20 and 50,

Your flood is talking but you need to listen better. There's lots of opportunity to improve your recovery and cash flow from this flood. Working this flood will add significant production and reserves. Call the flood improvement experts at Proven for help.

If X is greater than 50,

Ouch. You just inherited this flood from someone else, right? This must be the first time you've listened to this flood. You have some significant work to do here. If you can turn this one around, there will be a big bonus for you. Call the flood experts at Proven to help you get started.

?subject=Help me improve my flood&body=Help me improve my flood, increase sweep, increase recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0AMy quiz score: X=__________%0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We speak fluent flood.

Tags: Flood

Granger Low 15 Apr 2022

Granger Low 15 Apr 2022

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Celebrating 2025, a year of innovation

Oil and gas paradigm shifts this year

RTF: Most refused submission type in November

Leading indicators from industry

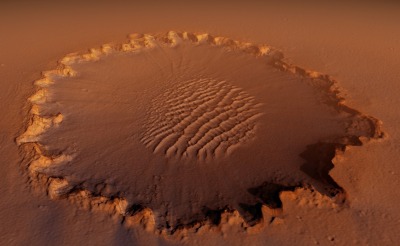

Astrobleme impacts deep well disposal scheme

Learn from the experience of other operators

Non-meridian thermal wells

Still drilling horizontal wells N‑S? Why?

Steam surfactant co-injection

Want to win? What is your competitive advantage?

Surprise! Sour gas production from a sweet thermal scheme

Dealing with surprises in the oil and gas industry. What to do next.

10 ways to increase production before Christmas - Infographic

For your wall to remind you

10 ways to increase production before Christmas

Each cost less than half a million

Using AI to reduce risk of oil and gas failure

How can you assess the risk without knowing the epic fails?

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share