CSS heat wave

Recover more bitumen - use less steam

What's the best way to operate CSS? What produces the most bitumen and uses the least steam?

What's the best way to operate CSS? What produces the most bitumen and uses the least steam?

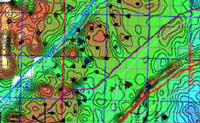

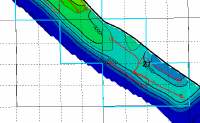

Cyclic steam stimulation (CSS) has many variants. One operator steams across patterns using a wave pattern. He believes steaming in a wave pattern introduces more gentle flexing of the overlying caprock, reduces cap rock fractures, lowers steam volume but increases recovery.

You can get his application documents within moments from our self serve application portal.

Get details of this cool tech Subscribers get them for free?subject=Help me with CSS best practices&body=Please help me with CSS best practices. %0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We stay on top of best practices from applications.

Wave history

The wave pattern was originally conceived to address thermal surface heave. Operators first used it believing that reduced steam can still improve recovery.

But CSS wave has advanced a long way since it was first used in 2011. Now operators believe that if they inject less at the ends of the pattern, they move the caprock in a smoother way preserving its integrity. They also list other advantages of steaming in a wave.

If you're using CSS and haven't considered wave steaming, you really should look into recent advances.

Leading indicators of thermal technology

You can't keep up with bitumen thermal technology by going to conferences. The technology changes way too quickly. Operators don't allow their employees to publish early results in technical journals.

The best way to keep up with technology is to watch applications. Each application is full of technology results and future plans.

SIRs - a gold mine of information

And applications are adjudicated by an engaged regulator focused on reviewing the working details of any scheme. Their supplemental information requests (SIRs) push operators to disclose even more details of technological plans. They reveal details of field operational problems.

Answers to SIRs show even more critical detail than the original applications. AppIntel includes the application documents, the supplemental information requests and the disposition documents. And you can get them in moments from AppIntel -- not days or weeks.

Appintel: do more with less

AppIntel costs less than a quarter of a person's salary. And it helps you find more intelligence quicker.

When coming out of a recession, companies have always turned to automation to improve the productivity of a leaner work force.

Just like carrying large loads by hand was replaced by hand trucks, and hand stitchers were replaced by sewing machines, so AppIntel can help your workforce become more productive. AppIntel presents applications on demand. It sends email alerts on new industry activity. It allows you to see your competitor's geological mapping. It helps you meet deadlines by understanding regulatory approval times.

Stay up to date on SAGD advances by email alert

Imagine if you could get an email alert every time a new SAGD application was submitted. You could use those alerts to stay abreast of new developments like this one. You can get unlimited alerts using AppIntel.

?subject=I want just a few email alerts&body=Sign me up for a few email area alerts. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:___%0D%0A%0D%0AType of applications___%0D%0ACentered on this UWI___%0D%0ARadius proximity from there___%0D%0A%0D%0APricing: www.appintel.info/just-alerts/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to buy just a few cheap and cheery email alerts.

Tags: Thermal, Heavy Oil

Granger Low 17 Nov 2016

Granger Low 17 Nov 2016

Supercharge 2026 with exploration AI skills that matter

Found a corner shot in thermal scheme

Don't blow the lid

Fracking into a neighboring well causes a blowout

Continuing Canadian thermal innovation doubled oil production

Experimental Propane Solvent co-injection in thermal

Shale in SAGD

How shale much is too much shale? Ask AppIntel AI.

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI shows SAGD type logs

Check out the picks and cap rock

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share