9 potent ways to enhance steam injection: SAGD

Methane, propane, solvent or surfactant?

If you want to save cost, what is the best fluid to inject with steam? Operators are co-injecting many different fluids in the field to improve their SAGD operations.

If you want to save cost, what is the best fluid to inject with steam? Operators are co-injecting many different fluids in the field to improve their SAGD operations.

Adding the right injectants can both decrease your operating cost and increase recovery in your SAGD operation.

But if you do it wrong, it might just seem like you're flushing money down the well. You need to learn what others have already tried and measure their success and failure.

Technical papers are fine. Simulations are great. But actually seeing these steam additives in the field takes the surprises out of the equation.

Reduce cost OR increase recovery

Some injectants take the place of steam. They are mostly designed to cut down the steam generation requirement. Steam is very expensive to generate. Reducing the steam-oil ratio (SOR) can drastically reduce capital and operating costs.

Some injectants change the solubility and viscosity of bitumen by chemistry. Steam aims to change bitumen viscosity by changing the reservoir temperature. But solvents change the viscosity chemically by mixing with the bitumen.

Look back at the field trials of others

It makes sense to see what others have done in the field. A field "look back" needs to consider the operator's intentions and their actual results.

The best way to conduct a look back is to read the application documents of others. These documents show their intentions and promises to the regulator.

?subject=Help me review new thermal bitumen recovery technology&body=Help me reviewing new thermal bitumen recovery technology%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We keep abreast of all the new thermal technology.

They also indicate the actual UWI locations of the proposed operation. Using these locations, you can review injection and production history and draw your own conclusions about success or failure of the field trial.

Ever wonder how steam additives worked in the field? You can find out by reviewing these nine applications by other operators. Just follow the links to get their application documents.

1. Methane and steam injection primer

1. Methane and steam injection primer

You can think of a SAGD scheme as a two dimensional graph with axes of Steam injection and Methane injection. Some schemes are inject steam only. Many schemes are injecting both steam and methane. Find out when one operator thinks is the best time to inject methane in the life cycle of a SAGD project.

2. Methane or Propane?

2. Methane or Propane?

Some operators are experimenting with each in the same field. One operator is a proponent for injecting propane into his thermal operation. On top of saving steam generation costs, water processing and disposal costs, he believes he will generate 25% more bitumen recovery.

And later, you can produce all your propane back for resale.

?subject=Help me find all the steam-propane injection schemes&body=Sign me up for a one day AppIntel trial so I can check out find all the steam-propane injection schemes. %0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0APricing: https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us for a cheap and cheery trial.

3. Solvent SAGD backgrounder

3. Solvent SAGD backgrounder

One early solvent trial is very interesting in its description and simulation of the solvent process.

Even before the operator decided to start construction, she decided to include solvent as part of her recovery process.

4. Propane injection and infills

4. Propane injection and infills

One operator is experimenting with propane injection in a SAGD pair and adding infill producers. He believes that this will increase recovery of bitumen outside steam chambers and also reduce steam requirements. He describes his patented process complete in detail and reveals projected recovery factors. He also has conjectures about the interaction of solvent with non-condensable gas.

5. Butane injection

5. Butane injection

One of the oldest solvent SAGD field tests is still getting changes and testing. Its operator has started several butane solvent co-injection projects and now is testing propane.

6. Mixing diluent downhole

6. Mixing diluent downhole

One operator with mature thermal knowledge has ended an experimental scheme mixing diluent downhole. In his application, he reports the findings of his 10 year study. He believes recovery improved and has plans to extend his pilot.>

?subject=Help me get up to speed on new thermal projects.&body=Help me get up to speed on new thermal projects.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We watch the leading indicators of the industry.

7. Reduce steam oil ratio with surfactant

7. Reduce steam oil ratio with surfactant

One operator believes that by injecting surfactant in a SAGD pattern he can change the emulsion production from oil/water emulsion to a water/oil emulsion and therefore reduce inter facial tension. He hopes this will increase bitumen recovery without any additional steam generation.

8. Surfactant to heal hot spots

8. Surfactant to heal hot spots

One operator documents his attempt and improving injection conformance by injecting surfactant into SAGD hot spots. His application documents the thinking behind this technology for reservoir path healing.

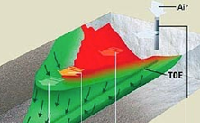

9. Toe to heel Air injection

9. Toe to heel Air injection

Toe-to-heel air injection (THAI) was an enhanced bitumen process that was touted to be the best and cheapest recovery process.p>

We've given you 9 applications that document field trials of steam co-injection, but there are many more. Some of these strategies could drastically improve your thermal scheme.

You owe it to yourself and your investors to read the application documents that explore these pilot projects. You decide whether they will work for your field.

You can help yourself to their application documents by using our self serve, secure check out. Follow the links above to buy these documents now.

All these have been passed the theoretical phase and lab test phase. Each has been implemented in the field.

?subject=I want a one day trial of AppIntel to research applications like mine&body=Sign me up for a one day AppIntel trial so I can check out thermal applications like mine. I want to to see their technology.%0D%0A%0D%0AMy Name:___%0D%0AMy Phone Number:____%0D%0A%0D%0AType of applications:___%0D%0A%0D%0APricing: https://www1.appintel.info/short-term-search/%0D%0A%0D%0A(Or call AppIntel Sales at 403-803-2500.)">Contact us now to try it cheap and cheery.

Tags: Thermal, Cut costs, Heavy Oil

Granger Low 4 Apr 2017

Granger Low 4 Apr 2017

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

New flood to double reserves for heavy oil pool

The age of water floods is not over

Flood repatterning

Extended life support

AI makes opportunity more accessible than conferences

Which sources of technical information do you trust?

Repairing microannulus in thermal wells

Check out the 4D seismic chamber thickness map

In-house AI attempts fail-80%

Spin off your in-house AI attempt

Facility fugitive emissions scrutiny

Keep your eye on the horizon of oil and gas change

AI predicts the future for 2026

using leading indicators

Celebrating 2025, a year of innovation

Oil and gas paradigm shifts this year

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share