The shocking reason for most flood failures

Are you still plugging injectors?

This post is brought to you by one of our information partners, Proven Reserves Exploitation Ltd.

Floods fail every day. Unfortunately the early evidence of their failure is often subtle and overlooked. Early detection of poor water flood performance can improve results dramatically.

Floods fail every day. Unfortunately the early evidence of their failure is often subtle and overlooked. Early detection of poor water flood performance can improve results dramatically.

Without AppIntel, you can't discussions of poor injectivity in the field. By using AppIntel, you can find operator's reports of flood failure to the regulator.

One operator disclosed that poor injectivity in his gas injector was reducing his voidage replacement and making his flood fail. By the way, this flood is for sale.

Help yourself to the pertinent application pages through our self-serve application documents library.

Get details of this cool tech Subscribers get them for free?subject=Help me get more from my old flood&body=Help me tune up my old flood, improve recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for help. We add over $20 million of reserve value ninety-five percent of the time when we tune up a flood.

Tight injectors are the first mistake

Choosing a tight well as an injector candidate is often a costly first mistake. How do you maintain voidage replacement without injectivity?

Injector conversion: Which to choose?

The production engineer wants to convert the worst well in the pool to injection. Why lose a great producer to injection? Convert one of the edge, wet, or tight wells that doesn't produce much.

The reservoir engineer wants to convert the best well to injection. He wants to support many producers with injection from just that one injector. He wants to support the entire pressure decline of the pool with just one injector. That injector needs to take a lot of fluid.

Pool injectivity and flood success will depend a lot on your injector choice.

Injector plugging

Even after you select a good injector, maintaining injectivity takes work. Many factors reduce injection capability over time.

The gradual decay of injectivity can be suggested by the increase of wellhead injection pressure over time. But if nobody is watching those pressures you may not find out about the problem until injection is finally suspended.

If you don't notice the reduction early, you will end up getting too much water into the wrong places in the pool and limit recovery. Eventually you won't be able to get enough water into the pool for good support and sweep.

?subject=Help me improve my flood&body=Help me improve my flood, increase sweep, increase recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0AMy quiz score: X=__________%0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We speak fluent flood.

Scale, fines, phase block

Scale precipitates can plug an injector. An acid wash may be able to remove some scale. Always check injectant compatibility to avoid surprises.

Fines in the rock might plug your injection perfs. Smectite clays swell in fresh water. Kaolinite clays roll to block pore throats. Testing core to determine clay hazards is always best.

Some water and oil mixtures can create an emulsion that will block pore throats. Checking oil and water compatibility is standard procedure.

Flood maintenance - Pattern balancing

Pattern balancing can detect and correct injector plugging and should be completed every year. It also brings many other benefits.

Pattern balancing brings the quickest, easiest and cheapest reserve adds. It's also one of the cheapest ways to add production. It has the lowest finding costs of any operation.

We've seen many out-of-balance floods sold three times to different operators without being balanced. Of the 1000 active floods in Alberta, we estimate that only 50 have been balanced in the last three years.

?subject=Help me balance my injection patterns&body=Help me balance my injection patterns, increase sweep, increase recovery and increase production.%0D%0A%0D%0AMy Name:__________ %0D%0AMy Phone Number:__________ %0D%0A%0D%0A(Or call Proven Sales at 403-803-2500.)">Contact Proven for support. We can predict the extra reserves.

Proven has several ways to fix floods. Our Optiflood tool can improve recovery. We add $20 million of reserve value to 95% of the flood we review.

Check out the results

Textbooks and classes may help you understand a bit about the general principles of flooding. But if you really want to understand how floods perform in the field, you must read others' flood application documents. They report progress on floods to the regulator. Each application is ground truthed to actual UWIs. Each application is adjudicated by a picky regulator.

How would you find these applications without AppIntel?

Beautiful people listen to their floods

Beautiful people listen to their floods

Your water flood is trying to get your attention. There are a few very simple steps to learning your first words in its language.

Beautiful people don't turn a deaf ear to their floods. They know that well run water floods add reserves and production for a long time.

Tags: Tight, Gas Injection, Flood

Granger Low 14 Jan 2019

Granger Low 14 Jan 2019

Supercharge 2026 with exploration AI skills that matter

Found a corner shot in thermal scheme

Don't blow the lid

Fracking into a neighboring well causes a blowout

Continuing Canadian thermal innovation doubled oil production

Experimental Propane Solvent co-injection in thermal

Shale in SAGD

How shale much is too much shale? Ask AppIntel AI.

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI shows SAGD type logs

Check out the picks and cap rock

AppIntel AI hit alerts

Ignite your insight

Blowdown and NCG injection

SIRs often reveal more than submissions

AppIntel AI contains much more than technical papers

More current. More coverage. More detail. More trusted.

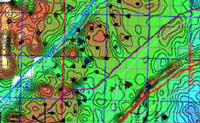

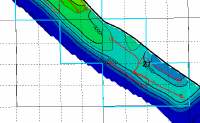

AI provides access to regional seismic mapping

Find it with AppIntel AI

New flood to double reserves for heavy oil pool

The age of water floods is not over

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share