Life after ASP - Saving cost

You can see what worked, and what didn't work at all.

Quietly this operator is removing the requirement to inject polymer from her flood. This ASP flood was approved six years ago. Now the operator will just inject water. Is this a cost saving initiative? Is it abandoning a failed flood? Did the operator get tired of the operational problems that go with an ASP flood? Reading applications can help you find out. We found this using AppIntel.

Quietly this operator is removing the requirement to inject polymer from her flood. This ASP flood was approved six years ago. Now the operator will just inject water. Is this a cost saving initiative? Is it abandoning a failed flood? Did the operator get tired of the operational problems that go with an ASP flood? Reading applications can help you find out. We found this using AppIntel.

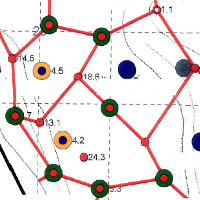

Since each application is ground-truthed to a UWI, you can look at this application and compare it with historical production. You can see what worked, and what didn't work at all. You can review the injection patterns established from an application. You can compare actual production to the plan proposed to the regulator.

Each AER application contains your neighbor's perspective on the exploitation of oil and gas formations. Applications contain more technical data even than SPE papers.

Would you like to see what other operators in your areas are thinking about seismic, multifractured wells, polymer schemes and recovery? AppIntel can help. Click the button below to get these application documents within moments.

Get details of this cool tech Subscribers get them for freeTags: Polymer, Flood, Cut costs

11 May 2016

Experimental Propane Solvent co-injection in thermal

Continuing Canadian thermal innovation doubled oil production

Measuring the rate of oil and gas technology growth

Energy transition inside the oil industry

The rise of water recycle

Join or perish

AppIntel AI hit alerts

Ignite your insight

Calgary, Alberta, Canada

Calgary, Alberta, Canada

Share

Share